Galvanizing categories: Meaning and application for batch galvanizing

14.10.2020 | Salzgitter Flachstahl GmbH

For corrosion protection reasons, steel is often hot-dip galvanized. A distinction can be made between continuous strip galvanizing and batch galvanizing. In principle, all common types of structural steel can be protected against corrosion by batch galvanizing.

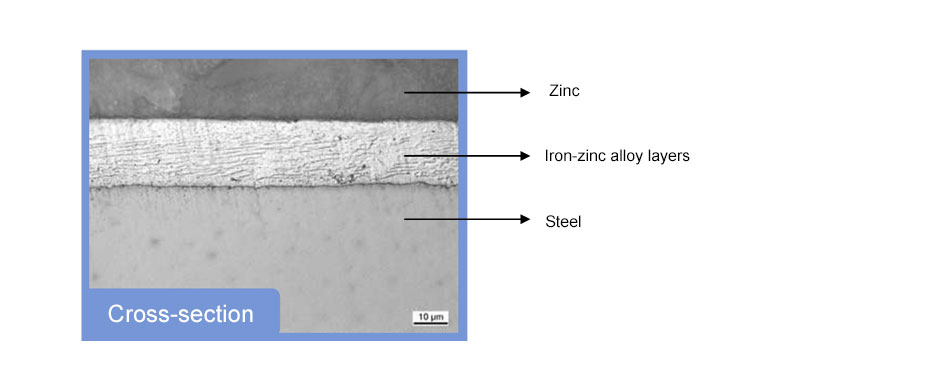

In batch galvanizing, steel parts are coated with a zinc coating by dipping them into a hot zinc melt of approx. 450 °C. When the components are pulled out of the zinc bath, the steel is coated with a zinc layer. The reaction with the iron in the steel results in iron-zinc alloy layers, over which a pure zinc layer is deposited. (see Fig. 1).

In batch galvanizing the appearance and thickness of the zinc coating can be influenced by the chemical composition of the steel. In particular, the silicon and phosphorus content play a significant role in the formation of the zinc coating, as these elements influence the rate of reaction of iron with zinc.

For an easier distinction, four categories (see Table 1) have been defined for batch galvanizing or hot-dip galvanizing of steels according to their chemical composition.

| Category | Element contents according to DIN EN 10025 |

| A | Si ≤ 0,03 % and Si + 2,5 x P ≤ 0,09 % |

| B | 0,14 % ≤ Si ≤ 0,25 % |

| C | 0,03 % < Si < 0,14 % (not normatively named) |

| D | 0,25 % < Si ≤ 0,35 % |

Tab. 1: Galvanizing categories based on DIN EN 10025-2

The main representatives of steels intended for batch galvanizing correspond to categories A and B. These usually stand out due to a silvery shiny zinc coating and lower layer thicknesses. Zinc coatings with a matt-grey appearance and higher layer thickness are achieved with category C and D steels. Due to the higher layer thickness, the protection period is longer. However, the extremely high layer thickness may reduce the durability of the surface against damage during use.

DIN EN ISO 14713 describes in detail the principles, conditions and recommendations for zinc coatings for the protection of iron and steel structures.

Depending on the requirements and use, the technical delivery conditions for steels for batch galvanizing have to be agreed between the customer and the steel manufacturer.

Salzgitter Flachstahl GmbH provides the corresponding steel grades of galvanizing categories A and B with the structural steels in accordance with DIN EN 10025.